Finding the Best Tissue Converting Solution

An Introduction to Tissue Converting

Tissue converting solutions are necessary for the production of tissue products on a large scale. There are numerous tissue converting solutions out there that can provide different benefits to the user, but one must choose the best for their needs based on several factors.

Factors to consider when choosing the best tissue converting solution:

1. Production efficiency:

The production efficiency of a tissue converting solution is of primary importance. The solution must be capable of producing large quantities of tissue products per unit time while maintaining product standards.

2. Cost-effectiveness:

The second factor would be the cost-effectiveness of the tissue converting solution. The solution must be affordable and must provide a high return on investment (ROI) by minimizing product wastage.

3. Flexibility:

The third factor is the flexibility of the tissue converting solution. The solution must be adaptable to different tissue products and must be capable of accommodating various product designs with ease.

4. User-friendliness:

The fourth and important factor is user-friendliness. The solution should have a user-friendly interface that makes it easy to operate and maintain.

5. Quality:

The fifth factor is the quality of the tissue converting solution. The solution should meet the product standards set by the manufacturer to ensure that the end product is of high quality and durable.

In conclusion, while selecting a tissue converting solution, one must consider these important factors, and only then can they choose the best option for their production needs.

Tissue Converting Solution Types

Overview of different types of tissue converting solutions

There are different types of tissue converting solutions available in the market, each with its unique features and benefits. Some common solutions include:

- Embossing machines

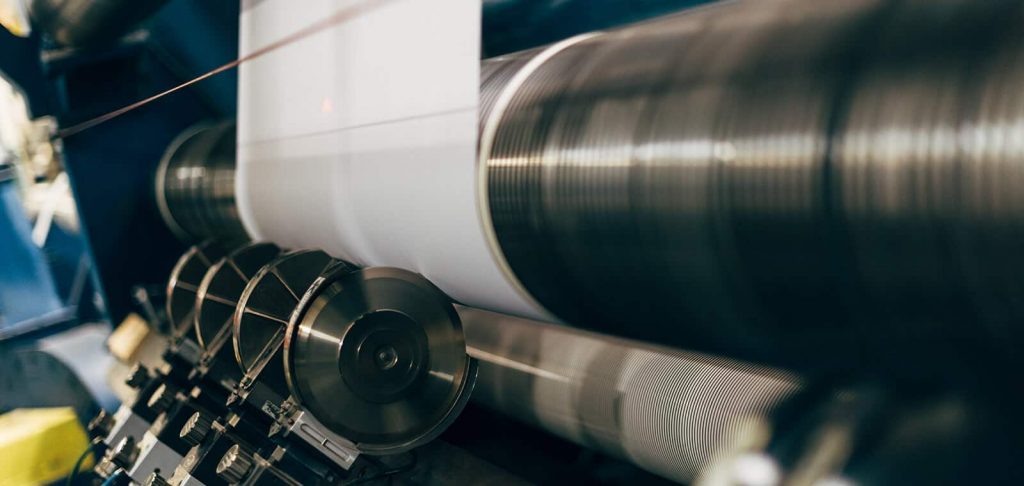

- Rewinding machines

- Log saws

- Napkin machines

- Folding machines

- Packaging machines

Advantages and disadvantages of each type

Embossing machines are used to create texture on tissue products, which adds to their appeal. Rewinding machines can convert large-sized tissue rolls into easily manageable ones for packaging. Log saws are used to cut tissue logs into smaller pieces for packaging. Napkin machines are used to produce napkins in different sizes and designs. Folding machines are used to fold tissue products into specific shapes, while packaging machines are used for packaging processed tissue products.

Each of these solutions has its own advantages and disadvantages. For example, embossing machines can increase the value of tissue products, but they may slow down production and increase costs. Similarly, packaging machines can increase production efficiency and minimize wastage, but they require significant capital investment and maintenance costs. Thus, choosing the right tissue converting solution requires careful consideration of these factors.

Rewinding and slitting on 5 rewinders going up to 143” width core sizes 3” to 16“ – All paper and board grades, from 12 lb. tissue to 52 pt. board, as well as woven and nonwoven grades, plastic, PVC and film.

Quality Control

Importance of quality control in tissue converting solutions

Quality control ensures that tissue converting solutions produce consistent, high-quality products. Consistency is necessary for customer satisfaction and brand image. Poor quality products can damage the reputation of a tissue converting business. Additionally, ensuring quality control can improve product safety, reduce waste, and minimize costs from returns and reworking.

How to ensure consistent quality control

There are several ways to ensure consistent quality control in tissue converting solutions. Regular testing of raw materials, intermediate products, and the final product is necessary. Testing should include physical characteristics and quality assurance measurements. Documentation of testing results, maintaining equipment, and monitoring processes and personnel are also critical. Tissue converting businesses should have a quality control plan that outlines procedures, responsibilities, and measures to address any issues. Proper training for personnel involved in tissue converting processes is also necessary. By following these precautions, tissue converting solutions can provide customers with high-quality and consistent products.

Production Capacity

Determining the production capacity needed for tissue converting solutions

To determine the production capacity required for tissue converting solutions, businesses must consider several factors. These include demand forecasting, the type of product being produced, and the time required to manufacture each product. Businesses must also consider the availability of resources such as raw materials, labor, and equipment. By conducting a thorough analysis of these factors, tissue converting businesses can identify their production capacity needs and make necessary adjustments to meet demand.

Factors that can affect production capacity

Several factors can affect the production capacity of tissue converting businesses. These include changes in demand, staffing shortages, equipment breakdowns, and supply chain disruptions. Effective planning and management can help businesses anticipate and minimize the impact of these factors on production capacity. Additionally, investing in new equipment and technology can increase production efficiency and capacity. By being aware of potential factors that can affect production capacity and having contingency plans in place, tissue converting businesses can maintain a consistent and reliable production output.

Maintenance and Support

Importance of maintenance and support for tissue converting solutions

Maintenance and support are essential elements for ensuring the smooth operation and longevity of tissue converting equipment. Regular maintenance can prevent equipment breakdowns and extend the lifespan of machinery. Furthermore, having reliable support services can ensure that any issues are quickly addressed, minimizing production delays and downtime. With proper maintenance and support, tissue converting businesses can maximize their production capacity and minimize costs in the long run.

What to look for in maintenance and support services

When selecting maintenance and support services for tissue converting solutions, businesses should consider several factors. Firstly, the service provider should have a good reputation and experience in the industry. Moreover, the provider should offer comprehensive support, including routine maintenance and fast response times for emergencies. Additionally, the provider should offer training and guidance on equipment operation and maintenance. Overall, selecting a reliable maintenance and support service is crucial for ensuring the longevity and optimal performance of tissue converting equipment.

Customization Options

How to choose the best customization options for your tissue converting solutions

Customization options can optimize the performance and efficiency of tissue converting equipment, tailored to specific business needs. It is important to choose the right customization options to increase productivity and quality.

Firstly, businesses should identify their specific requirements and constraints, such as the size and type of product, production volume, and available space. Secondly, businesses should consider if the equipment is scalable, and if it can accommodate future growth. Thirdly, the supplier’s expertise and experience in customization should be taken into account.

Moreover, customization options should include the ability to integrate with other equipment and software systems for data collection and analysis. It is also crucial to ensure that all customization options are compliant with regulatory standards.

Overall, careful consideration of customization options can lead to significant improvements in tissue converting equipment performance and production efficiency.